An Innovation in Polymer Membranes Makes Chemical Filtration More Sustainable

Researchers discover an efficient, cost-effective way to purify molecules like CBD

An international research team has produced a new membrane filtration system that improves the efficiency of some of the most energy-intensive processes used by major industries today.

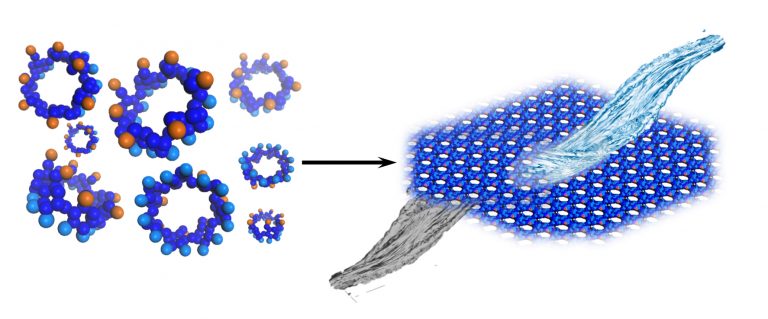

By developing a type of nanomembrane whose pores can be tuned through organic chemistry, the researchers have devised an innovative way to quickly filter chemicals with precision beyond conventional methods.

The findings, published in the journal Nature, can make the work of chemical and pharmaceutical industries more cost-effective and sustainable by reducing the energy required to separate and extract specific chemicals. About half of these industrial sectors’ energy consumption during production currently comes through molecular separation.

“Chemical separations are one of the most energy-intensive things humanity does,” said Austin M. Evans, PhD, assistant professor of chemistry and member of the Butler Polymer Laboratory at the University of Florida and one of the study’s authors. “By building better membranes, we can achieve higher purities, with lower costs, and lower carbon dioxide pollution.” The discovery, Evans said, makes it possible to “design the perfect membrane for any application.”

To control the pore structures in the nanomembranes, the researchers made use of macrocycles, a type of molecule with cavities that can be precisely tuned by organic chemists. The critical breakthrough came when Evans and his coworkers developed ways to align these macrocycles to create exact pathways for particular chemicals to pass through.

The study used the new membranes to enrich cannabidiol (CBD) oil, which requires separating CBD molecules from other chemicals in plant extracts. CBD oil has exploded in popularity in recent years among patients suffering from anxiety, depression and the side effects of cancer treatments. This rapid growth makes it an ideal application for a faster, less expensive and more accurate approach to filtering chemicals.

Evans collaborated on this study with Zhiwei Jiang, now an EPSRC Future Leadership Fellow at the United Kingdom-based polymer company Exactmer, and researchers from Northwestern University, Queen Mary University of London, Imperial College London, and Bielefeld University in Germany.

Read the full study here.